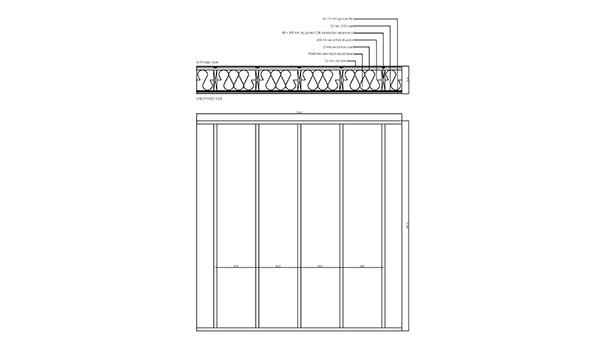

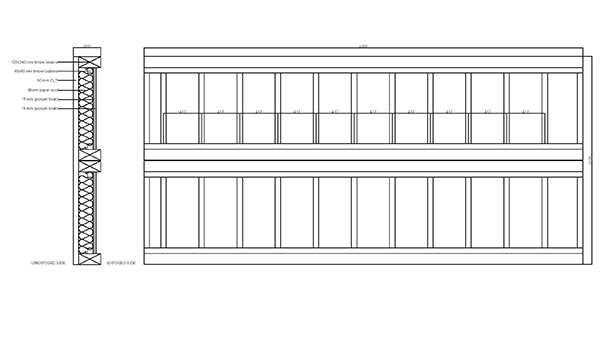

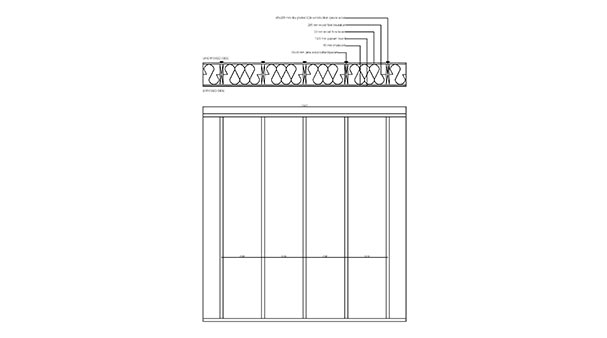

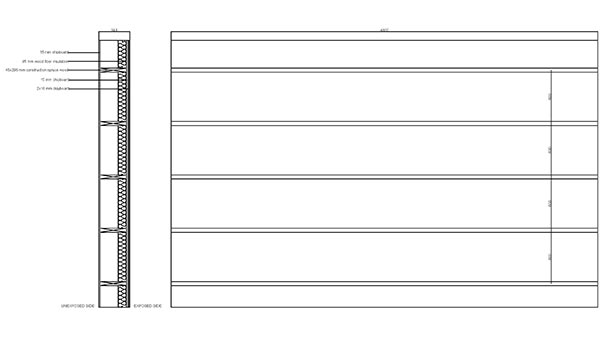

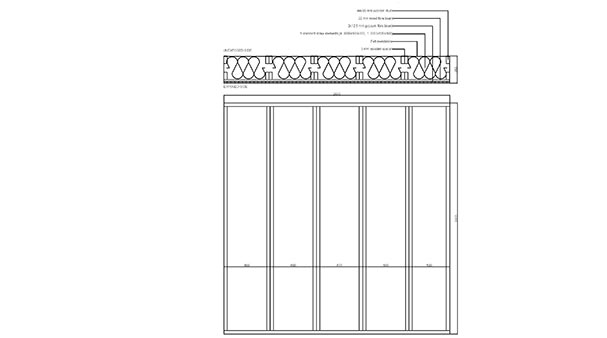

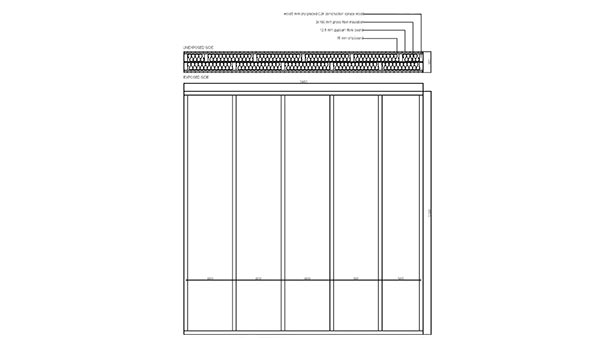

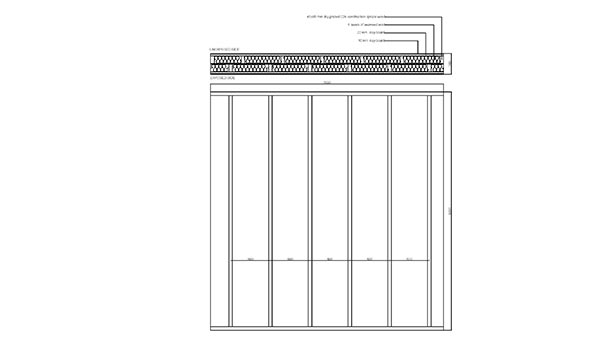

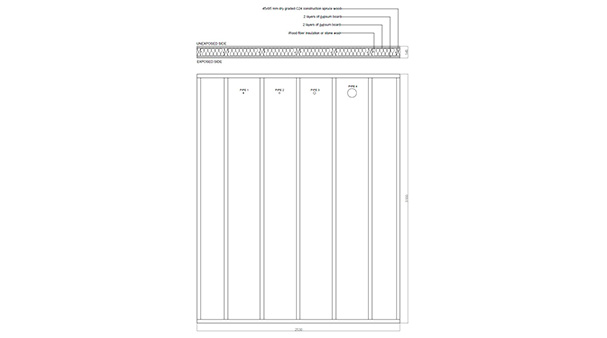

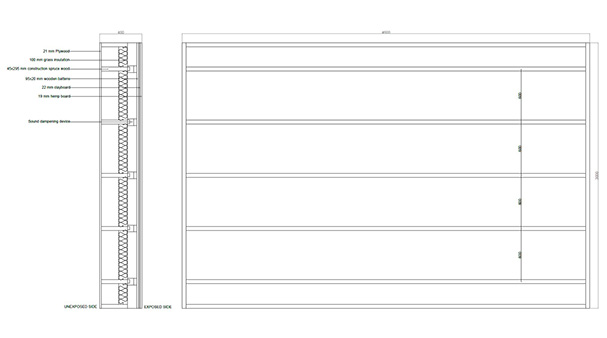

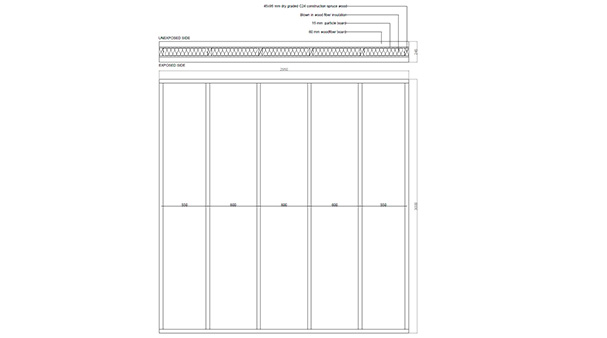

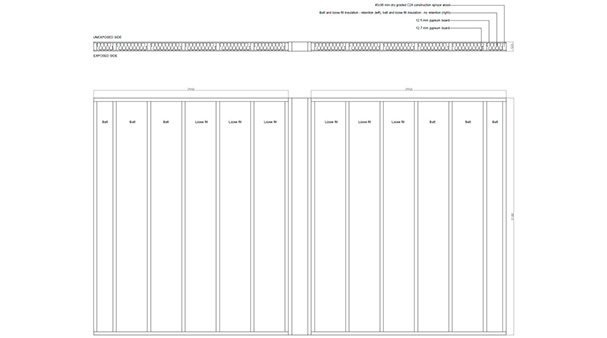

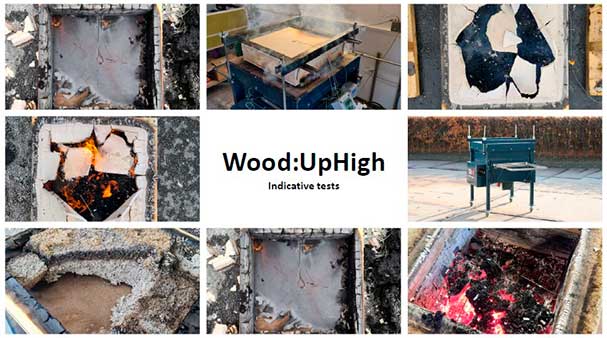

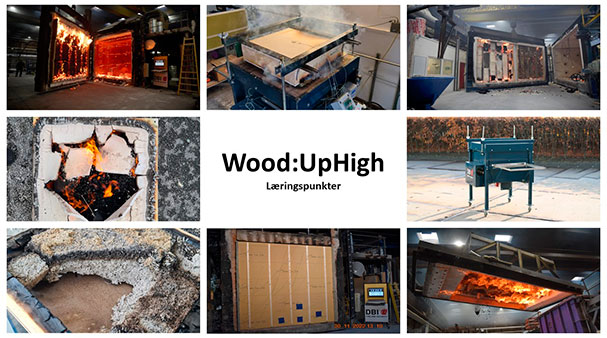

The construction of the test specimen:

Exposed side:

1. 12 mm chipboard

2. 18 x 46 mm pine wood studs/spacers

3. 22 mm wood fibre board

4. 45 x 295 mm C24 dry graded

construction timber with 295 mm wood fiber insulation blown in

5. 22 mm OSB3 board

6. 2 x 12.5 mm gypsum fibre boards

The fire test was used in a specific project to show the performance in an outside scenario. Although the test was conducted prior to Wood:UpHigh, its results have been incorporated into the example catalogue.

Target: REI60

Run time: 96 minutes