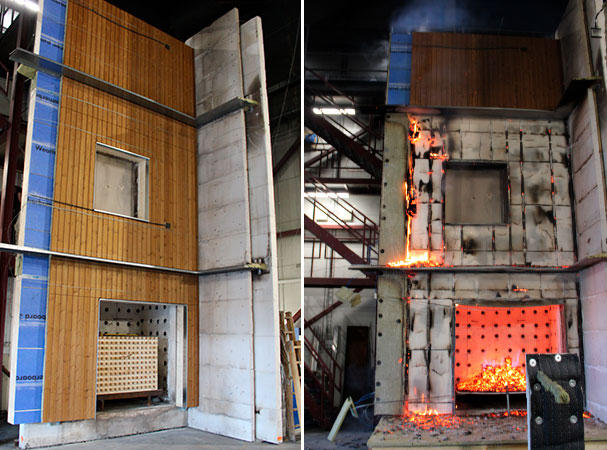

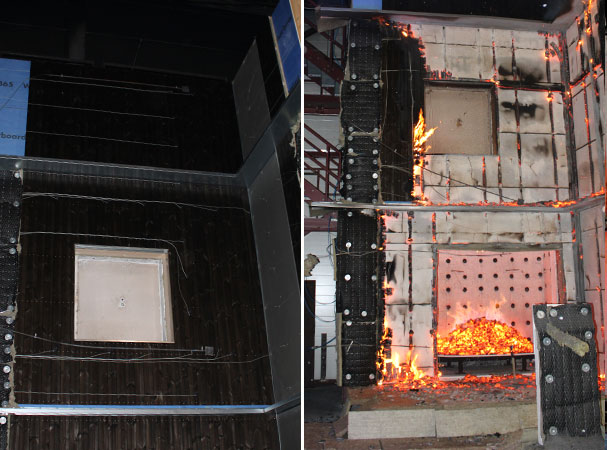

Construction of the test specimen:

- Pre-fabricated wood framed cassettes with 95 mm mineral wool insulation (Isover 34 Formstykker)

- Fibre cement boards 9 mm (Cembrit Windstopper Extreme)

- Two layers pressure impregnated formwork (forming 50 mm ventilation cavity)

- Vertical orientation 21 mm non-fire treated pine cladding (Moelven ThermoWood profil 581)

- 2 mm steel profile flame deflectors, extending 200 mm outside the cladding

- Window opening of 1200 × 1200 mm

- Construction also on the short wall

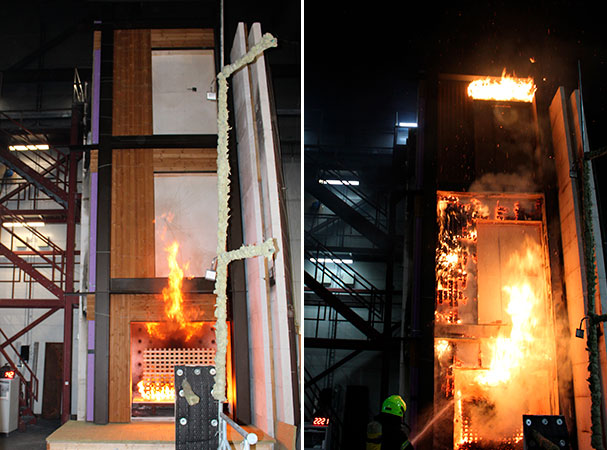

Vertical fire spread: 11 min

Horizontal fire spread: 10 min

Burning parts : 12 min

Falling parts(level 0): 12min

Click on the play button in the photo to watch a video from the fire test.