Published: 31.10.23

The test standard for walls with wooden panels has previously been inadequate, which has made it impossible to classify the panels. Years of work by DBI (The Danish Institute of Fire and Security Technology) has now made the test standard more accurate and enabled classification.

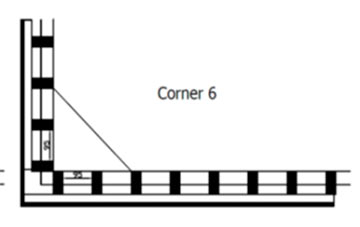

When an interior wall cladding such as wooden panels is to be fire tested, two walls with said cladding are fitted in a corner arrangement and then a gas burner is allowed to burn in the corner for 20 minutes. The test simulates a fire in a wastepaper basket in the corner and is used to classify the construction material according to how much and how quickly the fire spreads, as well as how much smoke and how many burning droplets the fire generates.

The test known as SBI (Single Burning Item) is a European standard that is integrated into the entire EN standard system. But Martin Pauner, a civil engineer at DBI’s fire test department, has pointed out a weakness in the standard, which means that manufacturers of wooden panels, for example, are able to have their products approved at a fire class that is higher than that to which the wall cladding material actually belongs.

The SBI test assumes that the corner is the worst place a fire can occur, as it will affect two surfaces instead of just one surface in the middle of the wall. However, this is not necessarily true for products such as wooden panels that do not form a single, level surface.

"Imagine that the wood manufacturer states in the installation instructions that the wooden panels should be fitted 30 centimetres from the corner of the wall, for example. This would mean that it would take a very long time before the heat from the gas burner in the SBI test reaches the panels, but this gives a misleading picture, because a real fire can occur anywhere along the panel wall – not just in the corner," explains Martin Pauner.

The EN 13823 test standard is a so-called end-use test, where the final construction and installation have a major impact on the test result. The misleading results arise because some products have installation instructions where the instructions for the corner appear to have been tailored to ensure minimal impact from the gas burner in the SBI test.

“These tailor-made corner geometries help to raise the fire classification of the product to an unrealistically high level, which is why DBI has taken an active part in this matter,” says Martin Pauner.

Together with international partners, Martin Pauner has worked on a 'position paper' that provides guidance where the test standard EN 13823 provides none. The paper takes a position on how linear products such as wooden panels should be fitted to ensure that the SBI test gives an accurate result. DBI has previously shown that there are at least nine different ways of fitting vertical panels in a corner, and the paper indicates how the panels should be fitted if the test is to result in a fire classification of the product.

It is DBI’s view that a SBI test of wooden panels, where the instructions in the new position paper are not followed, gives a misleading result as regards the fire properties of the wooden panels.

"If a wall cladding material that has undergone a SBI test ends up with a fire classification that is better than that which the product would have been awarded had the instructions in the position paper been followed, this could have serious consequences. It is important that we can rely on the results of these types of tests," says Martin Pauner.

"Now we have a method for fire testing solid wood panels in corners, both those that are '3-sided' which are fitted directly onto the underlying wall and those that are '4-sided' which protrude from the wall and are fitted to a support. And for vertically and horizontally fitted panels too," says Martin Pauner.

The method is based on a number of tests at DBI’s testing facilities. Martin Pauner particularly remembers a test on a panel product treated with a fire-retardant, which failed so emphatically using the updated testing method that the panel was actually comparable to untreated wood.

"This is of course of utmost interest to major wood producers, who would like to have their products CE-marked and awarded a B-s1, d0 rating. And for that matter, also to fire safety consultants who want to test a specific application of a product in order to get the solution approved," says Martin Pauner.

The new position paper also helps in relation to an imprecise formulation in BR18 which states that the product must be tested in end-use. DBI interprets the formulation to mean that the product must be documented for its end-use, and the new position paper enables this. Finally, the position paper also covers how the standard should take into account the testing of surfaces that are not flat, such as panels with a milled pattern.

This set-up meets DBI’s requirements for how vertical panels on non-combustible underlying surfaces are to be fitted for the purpose of a SBI test. Among other things, it is crucial that the two innermost wooden panels are adjacent to each other in the corner.

Contact:

Martin Pauner

Reaction to Fire Engineer